Design

(Calculations, Modelling & Drafting)

Products and Solutions are

designed considering customer experience,

supply chain,

competitiveness and ease of manufacturing.

Documentation package includes design guidelines & calculations, GAD's, parts list and purchasing &

manufacturing information

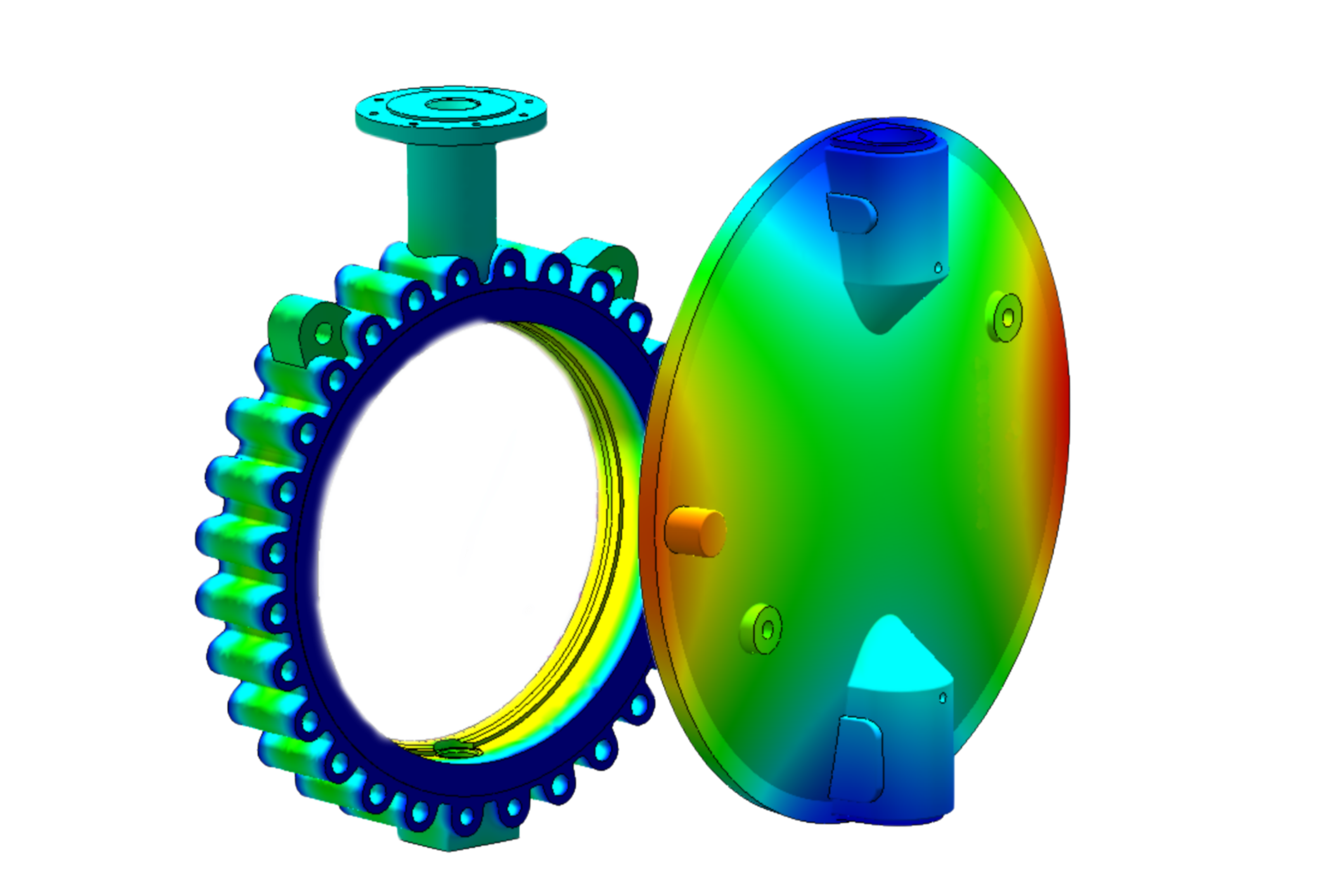

The Design process involves verification by Finite Element analysis, CFD analysis, Virtual assembly

analysis and Trend analysis etc.

Prototype

Partnering with supply chain

vendors during design stage allows

development of smart purchase & manufacturing specifications, assembly & test procedures and

inventory management recommendations.

This enables faster construction of prototype with minimum variation.

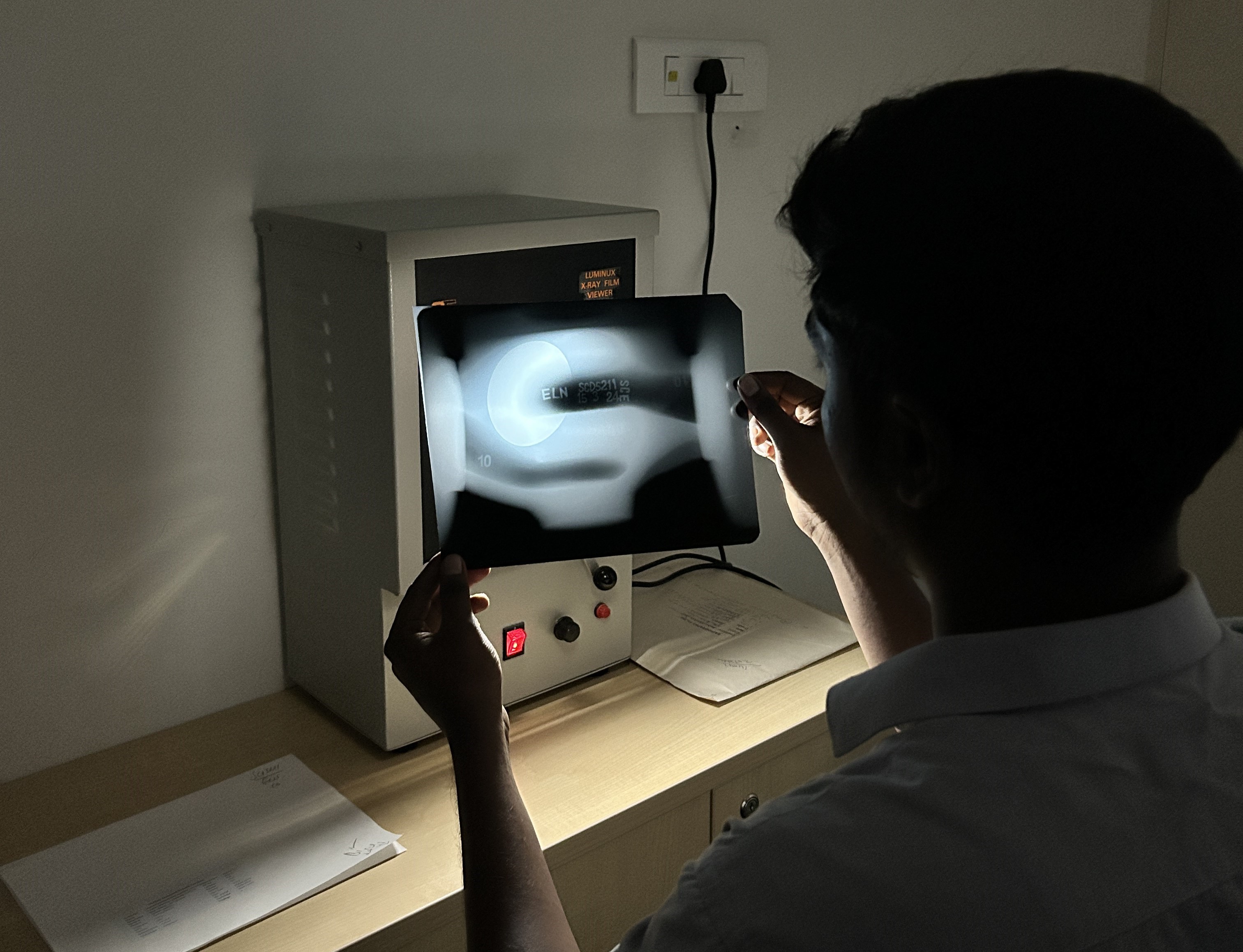

Validation

Complete test set up is designed based on test requirements of customers and standards. Product validation is completed and the product brochure, technical specification and instruction manuals are released.

Manufacturing

Product engineering manual for the complete line is created, including resource and capacity planning, QMS procedures, Quality plan, Manufacturing Assembly & Test procedures and Painting & Packing processes to the satisfaction of customers.