Control Valve Manufacturer in India – Globe, Butterfly & Actuator Solutions

Organization

is built with

Customer Focus & Innovation

People

We believe that our people are our greatest asset. With a dedicated team of 70

professionals, including 40 skilled engineers, we combine experience and

expertise to deliver excellence. Our team leaders bring an average of 26 years

of experience, while our entire team have an average of 10 years in the

industry.

At the heart of our philosophy is a commitment to people development and team

alignment, ensuring that every project meets its objectives and drives us toward

our ultimate goal: customer satisfaction and sustainable growth.

Processes & Tools

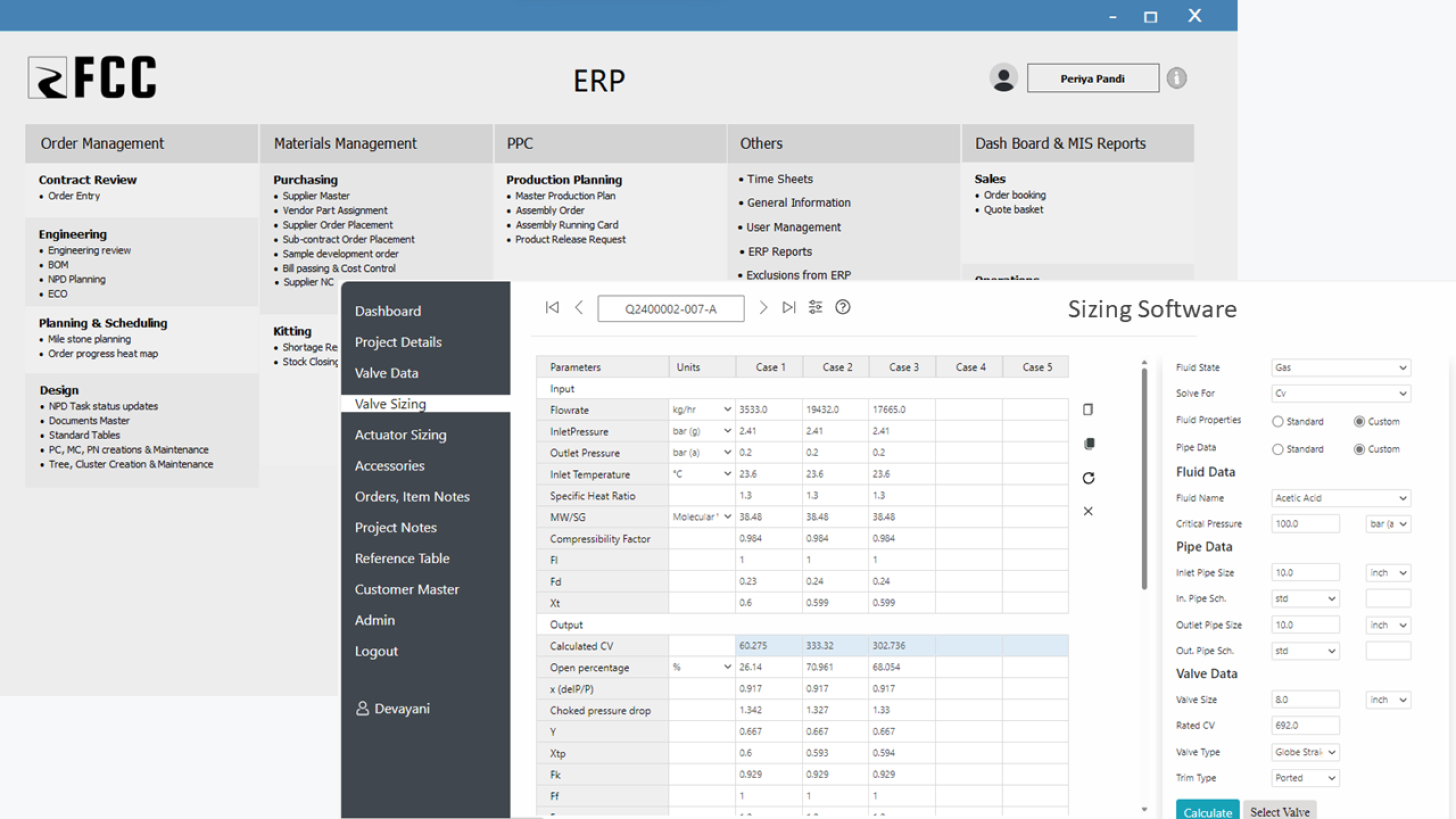

Our valve sizing software delivers accurate selection in full compliance with ISA

and IEC standards.

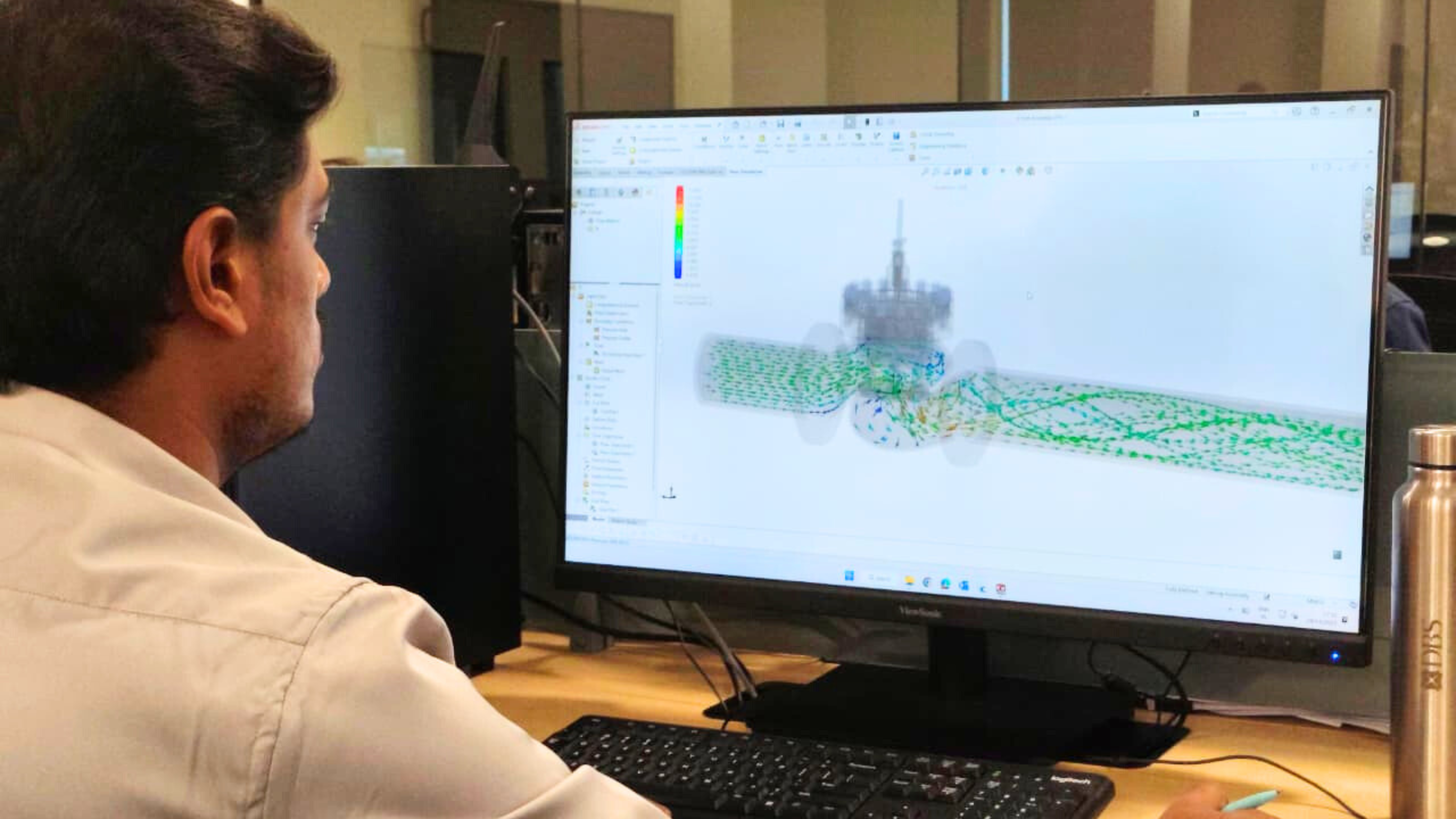

We use advanced tools for product design, PLM, FEA, CFD, along with BOM and GAD

automation to optimize engineering workflows.

From order entry and milestone tracking to MRP, inventory planning, vendor quality

management, PPC, and product release, our integrated ERP platform ensures smooth

operations.

With a strong foundation of authentic QMS and in-house designs, we enable continuous

improvement across all processes.

Design

Products and Solutions are designed considering customer experience, supply chain, competitiveness and ease of manufacturing. Documentation package includes design guidelines & calculations, GAD's, parts list and purchasing & manufacturing information. The Design process involves verification by Finite Element analysis, CFD analysis, Virtual assembly analysis and Trend analysis etc.

Prototype & Validation

Collaborating with supply chain partners from the design

stage enables the creation of optimized purchase and manufacturing specifications,

along with assembly, testing procedures, and inventory planning guidance. This

approach ensures faster prototype development with minimal variation.

Comprehensive test setups are developed in accordance with customer requirements and

industry standards. Once validation is complete, the product brochure, technical

specifications, and instruction manuals are finalized and released.

Space & Material Handling

Fully geared with material handling (up to 7.5 Tons) equipment, storage racks and retrieval processes assisted by Bar code / RFID. Sufficient factory space of 40000 sq ft and a roof height of 10 Mts.

Assembly & Testing capabilities

Adequately Equipped to meet with Assembly and Testing requirements as per IEC 60534-4, ISA 75.19.01, ANSI B16.34, API 598 for hydro test, seat leak tests etc as a standard. Optional tests like Fugitive Emissions test, Cryogenic tests etc can be performed as per applicable standards / customer specifications. Our plant also houses a clean room with UV for assembly / testing of valves for O2 and other applications.

Inspection & Testing

Diligent incoming inspection rigor using appropriate instruments such as PMI,

CMM, MSLD. Fully qualified personnel to carry out in-process inspection and

certification.

In house MP / LP testing capability by ASNT level II / III qualified personnel

Packing

Prior to packing, each valve will undergo a final quality inspection to verify end

protection,

coating/painting quality, and nameplate or tag details.

The condition of the packing

box, valve support,

and moisture protection will be confirmed for every shipment. Shipping markings will

be applied

according to the customer’s specifications. Fumigation will be carried out as

required by the customer,

in accordance with ISPM No.15:2009 standards.

Supply Chain

Stringent Vendor qualification requirements, onboarding and periodic

surveillance audit processes for vendor management embedded in the ERP suite.

Ability to cater customer specified special chemistry, and other NDT (MP,LP, RT,

UT

etc) requirements along with secondary processing such as Hard Facing, NACE,

NORSOK (chemistry as well as coating) requirements etc.